LED strips are a DIYer’s dream come true. Believe me, I’ve gotten sucked into binge watching hours of LED project videos more than a few times.

Even though I found tons of really good ideas (and wasted many hours), I struggled to find one place where I could get all the information I needed to create my own project.

That’s what this guide is for.

This guide is meant to take you from complete beginner to finished project.

I will teach you how to select and install the right LED strips for your application. I will also teach you how to select and install the appropriate controllers and power supplies to match your LED strips. And along the way, I will answer common questions and share what tips I’ve learned.

Finally, at the end is a list of my recommended products for your LED strip project.

[adinserter block=”6″]

Types of LED strip chips

If you’re shopping for LED light strips, you’re likely to come across all kinds of letter and number combinations that are supposed to describe the strip you’re looking at.

What do the letters mean?

The letters in the description refer to the output color(s) of the LED chips on the strip.

If the letters are separated by a “+” or a space, it usually means that they are separate chips. If there is no space, it usually means they are all integrated into one chip.

When the LEDs are on separate chips, fewer lights can be packed into the same length strip.

RGB – Red, Green, Blue

An RGB LED contains three diodes (LED stands for Light Emitting Diode) on the same chip: one for each color. Each color is wired to its own channel. By adjusting the power delivered to each color (using a controller), any combination of colors can be created.

W – White

Typically a single “W” refers to a pure white (6500K). There’s no set standard so make sure to double check.

WW – Warm White

Warm white is usually 2700K, similar to the color of an incandescent bulb.

CW – Cold (or cool) White

Cold white is in the 6500K range, but check to be sure.

CCT – Color Correlated Temperature

CCT usually means that the strip includes two channels of white. One is a warm white and the other is a cool white. By adjusting the power delivered to each white channel, the strip can produce any white light equal to or in between the two LEDs. The CCT LEDs can either be both on the same chip or on separate chips.

Examples of common LED chip configurations:

| Label | Description |

| RGB | A single 3 channel chip with RGB LEDs |

| RGBW | A single 4 channel chip with RGB and white LEDs |

| RGB+W | One 3 channel chip with RGB LEDs and a separate single channel chip with white LED |

| RGB+CCT | One 3 channel chip with RGB LEDs and a separate 2 channel chip with cold white and warm white LEDs |

| RGBCCT | A single 5 channel chip with RGB, CW, and WW LEDs |

What do the numbers mean?

An LED strip description often includes a 4-digit number such as 5050 or 2835. The number usually describes the size of the chip.

For example, a 5050 LED chip measures 5.0 mm wide by 5.0 mm tall. Similarly, a 2835 chip measures 2.8 mm wide by 3.5 mm tall.

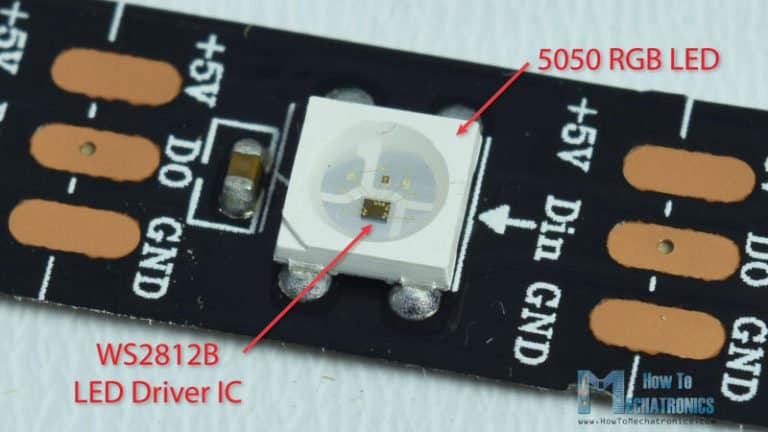

If you are looking at a digitally addressable strip, you will likely see a four digit number (for example, WS2812B or SK6812). But in this case, it has nothing to do with chip size. Instead, the number is the name of the integrated LED controller chip.

| Common addressable LED controllers: |

| WS2811 |

| WS2812 ECO |

| WS2812B |

| WS2813 |

WS2815 |

| SK6812 |

| SK9822 |

Does size matter?

Although most equal sized chips have similar characteristics, not all chip manufacturers are created equal. Therefore, there’s no guarantee that chips of the same size from different manufacturers have similar performance.

Generally a larger chip is brighter, but not necessarily. Ultimately, several factors determine the overall brightness including the chip circuit design, power consumed, and materials used.

For example, below is a table with basic specifications for three different chips made by Epistar (a popular LED manufacturer).

| LED | Chip Surface Area | Luminous Flux | Power consumed |

| 2835 | 9.8 mm2 | 22-24 lm | 0.2 W |

| 5054 | 27 mm2 | 45-55 | 0.5 W |

| 5630 | 16.8 mm2 | 50-60 lm | 0.5 W |

Notice how the 5630 puts out more light than the 5054 even though it has less surface area. Also, it manages to put out more light while still using the same amount of power (more efficient).

Size does play a role in determining how many LEDs can be mounted on a strip:

1. A narrow chip can be mounted to the strip more closely together creating a more uniform light.

2. A large chip can potentially fit multiple diodes on the same chip. This can allow for a better spacing for multi-purpose (color-changing) strips.

For example, an RGBCCT chip has 5 total diodes on one chip. The same chip is used continuously throughout the strip. Each chip can create colors and whites.

Compare that with an RGB+CCT strip. Two different chips are used. One creates colors and one creates whites. They are arranged alternately.

The distance between each similarly colored LED is greater on the RGB+CCT strip compared to the RGBCCT strip. In practice, the bigger gap can make the light less uniform.

How to choose the right LED strip

There are seemingly endless variations of LED strips that are being sold in a wide price range. What are the differences between cheap and expensive? And, what is best for your project?

Brightness

Brightness or luminosity is usually measured in lumens. For LED strips, the question you are interested in is, how bright is my strip per unit length? So rather than a total lumen amount, you should be looking for lumens/foot or lumens/meter.

Here are some guidelines for choosing a brightness level depending on the situation.

| Use | Suggested Lumen/foot |

| Accent/Mood lighting | 150-350 |

| Under cabinet lighting | 175-525 |

| Task lighting (close) | 275-450 |

| Task lighting (far) | 350-700 |

| Indirect lighting | 375-575 |

| Fluorescent tube replacement | 500-950 |

It’s a good idea to buy strips with extra brightness for your application. Then, get a dimmer to reduce the brightness to the desired level.

Using a dimmer will lower the operating temperature of the LEDs which will lengthen their lifespan.

Furthermore, as LEDs age, they do lose some of their luminosity. If you oversize your LEDs a bit from the beginning, you will have some extra brightness to make up the difference as they age.

Efficiency

Luminosity doesn’t always tell the full story. You can get more brightness out of any LED if you pump enough power through it, but that’s not always a good thing.

An LED strip manufacturer can increase the reported lumen output by overpowering the LEDs. This will cause them to shine more brightly, but will also cause them to get hotter and run less efficiently. Since heat is the main reason for an LED to fail prematurely, it’s likely that overpowered LEDs will not last as long as they otherwise could.

For that reason, it’s good to ask the question, how much light does it put out compared to power used? This ratio is called the luminous efficacy. It’s often listed in a products specs. If not, you can calculate the efficacy by dividing the number of lumens produced by how much power it uses.

Do I need a high CRI light?

Color rendering index (CRI) is a measure of how accurately an artificial light source replicates natural light. It is reported as a number from 0-100.

A CRI greater than 80 is acceptable for most applications.

A CRI greater than 90 is considered high CRI and is mainly used in retail, art, film, or photography. Some of the best quality LED strips have a CRI of 97-99.

Why is CRI important?

Objects under low CRI lighting may seem dull or harsh depending on the light and color. Colors will be less vibrant and the overall lighting effect will seem less bright.

But why is that?

NOTE: What follows is a technical explanation of what makes a high CRI light. You can skip it if nerdy stuff makes your eyes glaze over.

Light that we can see is usually not made up of a single wavelength. Rather, it’s a collection of waves that span the visible spectrum. The color the light appears to be is an average of the included waves.

As shown in the image above, different wavelengths correspond to what we see as different colors. The color of an object will be determined by the wavelengths of light it reflects.

For example, if the sun shines on an object and we see red, that means the object has absorbed all the wavelengths of light except for the light in the red wavelength region. That light gets reflected into our eyes causing us to see a red object.

Now what happens if instead of sunlight, we shine an LED light on the apple?

Well, if it’s a standard, low-cost LED, the result will likely be a dull, orangish and generally unappealing apple.

Why?

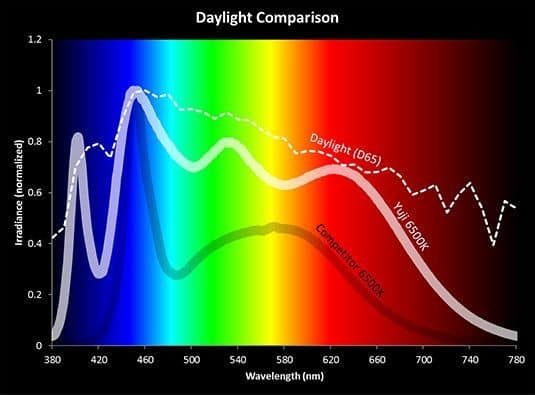

Sunlight at noon has a correlated color temperature (CCT) of 5500-6000K. You might think that in order to replicate daylight, you just need to buy an LED with the same CCT. But, it’s more complicated than that.

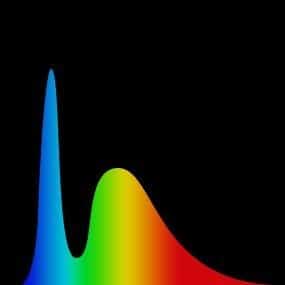

Any visible light can be broken down into its parts by measuring the power of the waves in a given wavelength range. This is often shown in graph form using a spectral power distribution graph. Below is a spectral power distribution graph of daylight.

A typical LED has a spectral power distribution graph that looks something like the image on the left. Notice there are significant deficiencies around the cyan and red areas. This will cause objects that include those colors to look “off” when viewed under these lights.

A high CRI LED has a more even spectral power distribution like the image on the right. This particular one is made by YUJILEDS.

Below is the same YUJILED compared to daylight (white dotted line).

An LED light can be built to give off a CCT of 6000K (to match daylight). But if the spectral power distribution doesn’t closely match natural light, objects will always look “off” when viewed under the light.

Is 12V or 24V Better?

LED strips are most commonly available in either 5V, 12V, or 24V.

For analog strips, most people will choose either 12V or 24V. Generally, 12V is perfect for small installations, but for large installations, it may be better to go with 24V.

For projects with digital strips, it can sometimes be convenient to use 5V strips. Most digital controllers run on 5V which allows the controller and the strips to be run from the same power supply. Furthermore, on 5V strips each individual LED can be independently controlled.

Higher voltage means longer runs

A higher voltage strip will generally be able to have longer runs without suffering from the effects of voltage drop.

What is voltage drop?

Voltage drop causes LED strips to lose their intensity as the strip becomes longer. LEDs at the beginning of the strip (nearest the power supply) will shine brightly. Whereas, LEDs at the end of the strip will have a dimmed appearance.

An example of voltage drop

Above is a great example of the effects of voltage drop.

A couple years ago, I installed some indirect lighting in my living room. I used 12V strips and made a loop around the perimeter of the room by connecting three 5m strips end to end to one power source.

The bright light on the left is the start of the strips. The lights travel around the room and end right next to the beginning. The lights on the right side are suffering from voltage drop and are much less bright.

Why does this happen?

Any length of wire has a certain amount of electrical resistance. The longer the wire, the more the resistance. Electrical resistance causes voltage drop and voltage drop causes your LEDs to dim.

Therefore, LEDs at the end of a strip will always be getting less voltage than the LEDs at the beginning. If you make the strip long enough, the drop in voltage will become significant enough to cause a visible difference in brightness.

How does higher voltage reduce the effects of voltage drop?

First, you have to have a basic understanding of how all the components on an LED strip are connected.

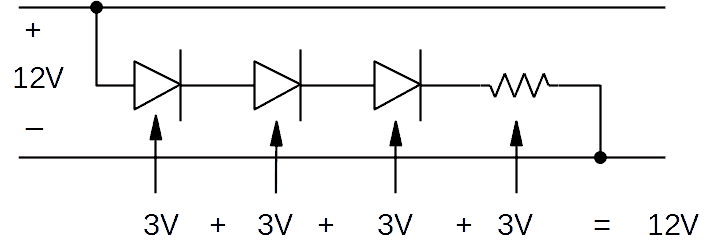

Most individual LED chips run on 3V DC power regardless of whether they are mounted on a 12V strip or a 24V strip. In fact, the same LED chip that works on a 12V strip could also be mounted on a 24V strip. What makes the difference is how the strip circuitry is designed.

LED chips are wired in series into groups. Each group contains some LED chips and a resistor. The total voltage drop across the group has to be equal to the total voltage of the strip (see diagrams below).

Then, each of the groups is wired in parallel and arranged along the length of the strip.

For now, take notice (above diagrams) that the group size on a 24V strip is 7 LEDs compared to only 3 LEDs for 12V. I will explain why this is significant below.

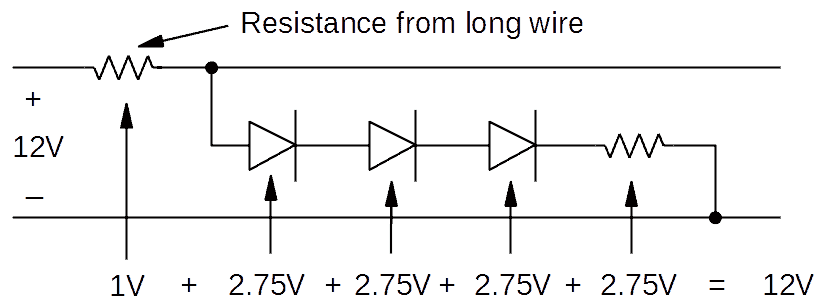

Every wire has a certain amount of resistance to electricity being pushed through it. The longer the wire gets, the bigger the resistance (and the voltage drop) gets. Eventually it gets large enough to impact the LED brightness. Below is an example of how it might happen on a 12V strip.

Notice in the above diagram that the voltage across the LEDs has dropped from 3.0V to 2.75V.

When we switch to 24V, two things happen that reduce the amount of voltage drop.

- When the voltage gets doubled (12V to 24V), the current is halved (Ohm’s law). That causes the voltage drop from the long wire to be reduced by half as well. So instead of a 1V drop, it becomes 0.5V drop.

- The effect of the 0.5V drop is split between the 8 remaining circuit components (compared to 4 on the 12V).

Notice here that the voltage across the LEDs has only dropped to 2.9375V compared to 2.75V with the 12V strip.

If you have an application that requires long runs of strips, it may be a good idea to us 24V strips. But, even 24V strips have a limit. You may have to use other techniques (see power section below) to stop your LEDs from fading at the end.

Lower voltage has Closer Cut Lines

As I just mentioned, LED Strips are wired in groups of LEDs. The size of the group depends on the voltage of the strip. A 5V strip will only have one LED per group, a 12V strip has 3, and a 24V strip has 7.

The cut lines are located between the groups. Therefore, the smaller each group of LEDs, the closer together the cut lines can be.

For example, see the diagrams of 12V and 24V strips below.

If your installation has many corners with short lengths between, a lower voltage strip with closer cut lines may be a good choice. This can help to minimize the “dead” spots at the corners.

Higher voltage can be more efficient

Any time there is voltage across a resistor, it means energy is getting converted to heat instead of light. Therefore, the resistors in the above diagrams are necessary, but they’re also a source of wasted energy.

How much is wasted?

The calculation is fairly simple. All we have to do is divide the amount of voltage across the resistor by the total voltage:

| Total voltage of strip | Voltage across resistor | % Power “wasted” on resistors |

| 5V | 2V | 40% |

| 12V | 3V | 25% |

| 24V | 3V | 12.5% |

It’s easy to see that higher voltage strips suffer from less wasted energy. LED’s use such a small amount of energy that this doesn’t add up to much for small installations. But, for whole room or commercial installations, the difference in power usage can become significant.

How thick is the copper?

The flexible strip that the LEDs are mounted on is actually a circuit board. Within the strip, there is a layer of copper that provides the electrical circuitry and the bulk of the heat dissipation.

For those reasons, the thickness of the copper layer matters.

A thicker layer of copper means electricity can flow through more easily (less electrical resistance). This will create less voltage drop and allow longer runs.

It will also dissipate heat more quickly. The LEDs will stay cooler, which will ultimately help to maximize their lifespan.

The amount of copper in an LED strip is usually measured in ounces per square foot. Typical values for an LED strip are 1oz-4oz. Higher power requires more copper.

Unfortunately, very few retailers list this on the product info page. If you’re planning a small project with some bargain level strips, I wouldn’t worry too much about it.

However, if you are planning a big project with high-quality strips, it would be worth contacting the manufacturer if it isn’t listed on the specs page.

How to install LED strips

The best way I’ve found to install LED strips is within an aluminum channel.

The channels are available either angled or flat, and with a diffuser cover or clear cover. They do come in different widths, so make sure the channel fits the strip.

You can cut the soft aluminum channels with a hacksaw or with an electric miter saw. If you use the miter saw, you should use a carbide tipped blade with lots of teeth.

Once cut to length, the channel can be firmly mounted using screws.

Benefits of installing LED strips inside a channel:

- Provides a uniform surface for the strip’s adhesive to form a secure, long-lasting bond.

- The aluminum acts as a heatsink and helps to dissipate heat for longer LED life.

- The plastic cover will diffuse the light. This will make the light from the LEDs appear more uniform.

- The cover will also help to protect the strip from dust and damage.

- If the LED strips are in plain view, the clean lines of the channels help to give the installation a more polished look.

Despite all the great benefits of the channel, there are installations where the extra cost of the channels just isn’t worth it.

The biggest problem you’ll have when installing without a channel is the strip’s adhesive not holding. It will usually stick initally. But sometimes a week or a month later, the adhesive will fail.

In order to make sure the adhesive doesn’t work its way loose, I recommend using a dab of hot glue every couple feet.

How to connect LED strips

Soldering is usually the most reliable method for joining two LED strips. But, it’s also time consuming, requires special equipment, and requires a bit of skill.

Clips are faster and don’t require any skill. For that reason, I recommend using clips if you’ll have easy access to the strips (most installations).

However, the connections made by the clips are not as permanent as solder. They are vulnerable to corrosion and movement.

Therefore, I recommend using solder if the strips may experience:

- Weather – any outdoor installation, or heating and cooling that could cause condensation

- Movement – any sort of flexible channel or location that might experience vibration

- Very permanent – enclosed in epoxy or other similar

How to deal with corners

The challenge with corners is to effectively turn the corner without leaving a “light gap” and without spending too much time fiddling with cutting and connecting.

Gentle bend

The best way I’ve found for most of my installations is just to create a gentle bend around the corner.

For this method, you don’t need to cut the strip or have any special connecting hardware. You can do bends even if strip components happen to land right on the corner.

Guide the strip around the corner and let the strip take its own shape. The result will be a small loop in the corner.

One problem with this method is over time the adhesive in the corner can be pulled up. To stop that from happening, use some hot glue on each side of the corner.

If you are installing the strips inside a channel, the bent area may not fit inside. This is especially true for strips with densely packed components. In that case, I recommend cutting the strip and using the corner connectors instead.

Corner Connector

You can also cut the strips at the corners and rejoin them with connectors. However, LED strips must be cut on their cut lines. Therefore if the gap between cut lines is large, you could end up having a small gap with no light in the corner.

This is an instance where installing the strips in a channel with a diffuser will be helpful. Without the diffuser, you will likely have a dim or dark spot.

You can buy rigid plastic 90 degree corner connectors, but I recommend the type with wires. The flexible wires can be adjusted to any angle.

Fold Method

You can try to fold the strips but I don’t recommend it. The PCBs on most LED strips are quite flexible. Make sure your bend will not put any stress on areas with any components. Low density single color strips work the best for folding because there’s more “clean” area available for a fold.

First, bend the strip at a right angle in the opposite direction of the turn.

Then, make a second bend by folding the bent end back over itself.

Remove LED strips

Once an LED strip is securely stuck to a surface, it can seem nearly impossible to remove it without destroying the strip.

Don’t just pull the strip and hope for the best. You will risk tearing the strip or damaging individual LED connections.

Instead, use floss.

No, not that kind of floss! Dental floss.

Cut a length of floss and slide it under an edge. Then, work it back and forth along the length of the strip.

How to power LED strips

LED chips are powered using DC (direct current). Therefore, you can’t plug an LED strip directly into the wall outlet (alternating current). Instead, you need a power supply to convert the AC power from the wall into DC power that the LED can use.

How to Select an LED Power Supply

This is an area that often gets overlooked especially among hobbyists. If you’re going to spend money, you probably want to spend it on some super bright, high-quality LEDs. Therefore, it’s tempting to cheap out on a power supply. But, spending the money up front on a good power supply will often pay for itself over time.

How much power do you need?

First, you need to know how much power your strips will use so that you can select a properly sized power supply.

Every vendor should list the power consumption of their LED strips. It may be listed as the power consumption of an individual LED chip or as the power per length of strip. Either way, just multiply the power per unit length by the total length of the strip you plan to use. That number will definitely be enough. However, in some cases it may actually be way too much due to how controllers manage your LEDs (this post explains more).

Don’t worry, it’s not necessary to get a perfectly accurate number. Close is good enough.

Once you have an estimate of the power usage of your strip, a good rule of thumb is to add another 20% (strip power / 0.8). Then, select a power supply that can provide greater than or equal to that amount.

The extra capacity will help to insure a long life for the power supply. As with LEDs, a common cause of power supply failure is heat. And running a power supply at full capacity will heat it up.

Power supply voltage must match the LEDs

The power supply must be the same voltage as the LED strip.

For example, if you try to use a 24V power supply on a 12V strip, the LEDs will shine very brightly (overpowered) for a short period of time. Before long, they will overheat and burn out.

Conversely, if you try to use a 12V power supply on a 24V strip, the underpowered LEDs will not light up at all.

Waterproof or not?

A power supply enclosure is usually rated using the IP rating system. The first number of the IP rating is protection against sold objects (e.g. fingers, dirt, dust). The second number is protection against liquid (e.g. dripping, spraying, immersion).

Waterproofing

If you’re looking for a waterproof power supply, I recommend making sure you get an IP67 or IP68. These are expected to be fully submersible.

You can also find power supplies with an IP65 rating marketed as waterproof. These are protected against water spray (e.g. heavy downpour, hose spray nozzle) but not submersion.

The price difference between IP65 and IP67-68 is usually minor, so the extra protection is worth it.

Dustproofing

Even if you’re not worried about water, you may want a sealed power supply to protect against dust.

Any power supply with an IP rating that starts with “IP6” will be sealed against dust.

If power supplies are open to the air, dust can accumulate on internal components. This contributes to excess heat build up which can shorten the life of the power supply.

Power supply efficiency

The efficiency of your power supply can make a big difference in total power usage. Typical efficiencies for power supplies run between 70% and 90%.

For example:

If I have an LED strip that uses 100W, a power supply with 70% efficiency will draw 100W/0.70 = 143W of electricity.

Whereas a power supply with 90% efficiency will only draw 100W/0.90 = 111W.

For the most part, if you want more efficiency from your power supply, you have to pay for it. Whether or not it makes sense to pay for more efficiency will usually depend on the size of your project.

Installing the power supply

If you plan to just plug your LED power into an existing outlet, you don’t need to worry about violating building codes. As long as you’re not tapping into mains voltage or running wires inside walls, you are in the clear.

However, if you’re doing a large installation, you probably don’t want wires hanging around everywhere. In that case, a clean install usually requires multiple LED driver power supplies and running wires through walls.

If you’d like to have a nice, clean look, consider putting all the power supplies inside an enclosure. Bring the line voltage into the enclosure and wire up an outlet within the enclosure. Then mount the power supplies and plug them into the outlet.

DO buy a class 2 rated power supply. If you are running wires within walls, this will make sure you don’t exceed power requirements. A class 2 power supply is limited to 60W for 12V and 96W for 24V.

A single power supply can exceed the power limit if it splits the power into multiple outputs as long as each output is within the power limits.

DO use class 2 compliant (CL2) wiring if you will be installing any wires inside finished walls.

DONT wire your power supply directly to line voltage. Instead, connect a 3 prong plug to the input (120V) side and plug it into an outlet.

DONT install the power supply inside a wall without an access panel. This should go without saying, but there’s always that guy. Power supplies do fail and if they’re stuck inside the wall, it becomes quite a maintenance headache.

How to power very long strips

If you have a long enough run of LED strips, you will experience voltage drop. You can reduce this problem by using higher voltage strips (as explained above), but that won’t solve the problem completely. Eventually, if the run is long enough, even a 24V strip will suffer the effects of voltage drop.

Fortunately, there are ways to extend the reach of your strips without too much trouble.

Install the power supply in the middle

The simplest way to double the effective length of your strips is to place the power in the middle of two strips. Similarly, if the strip makes a loop, you can connect both ends to the power.

Use power injection

Of course, sometimes you’ll be limited by where you can install your power supply. In other cases, you will have such a long run of lights that even placing the power in the center won’t be enough to avoid the voltage drop.

In those cases, you will have to run more wires to the locations that need it. This is called power injection.

Power injection can be done with one power supply or multiple power supplies. It’s done differently for analog and digital strips.

Power injection for analog LED strips

Analog strips don’t have embedded microcontrollers like the digital strips. That means that some kind of voltage controller needs to be installed between the power supply and the strip at all connections.

One option would be to buy a second controller. Essentially that would create a second LED strip with separate power and separate control. Then if you wanted to, you could use automation software to make sure the two controllers stay synchronized.

However, there’s a simpler (and cheaper) solution.

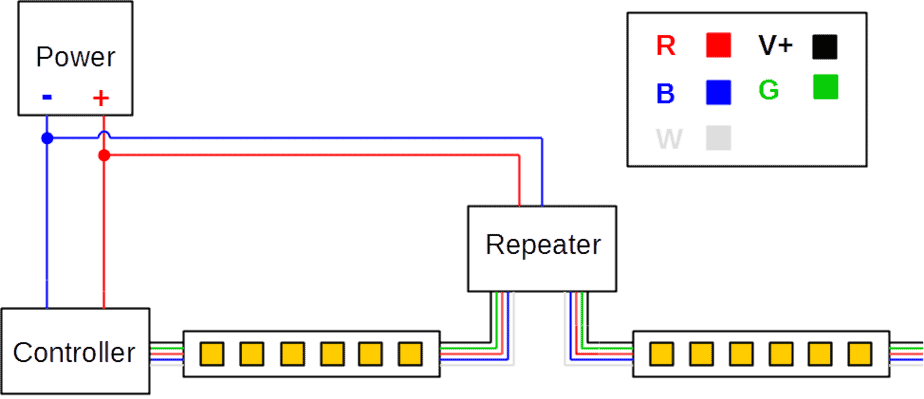

Signal Repeaters

A signal repeater can be connected anywhere that power injection is needed. The repeater will transfer the signal so that all LEDs are synchronized by a single controller.

This way is simpler for home automation because only the one controller is added to the smart home network.

It also makes the wiring for power injection simple. All you need to do is connect power to the repeater and wire the two strips to the repeater.

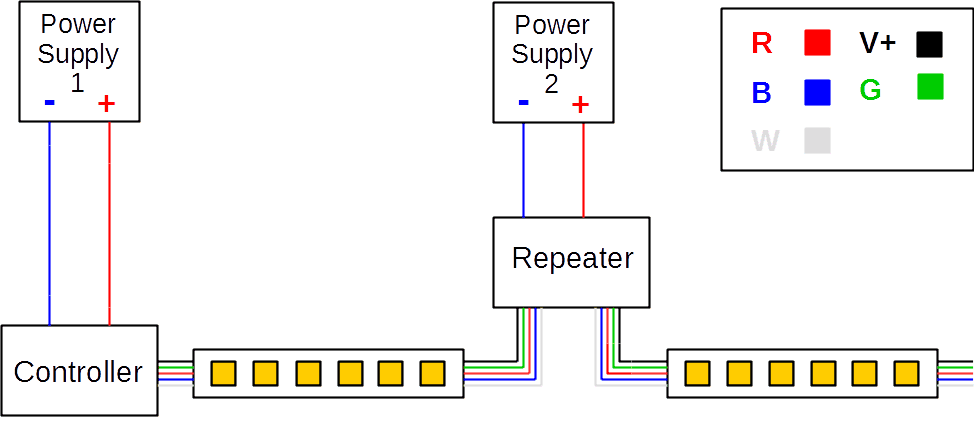

A repeater can be powered from the same power supply as the controller (above). Or, it can be powered from a separate power supply (below).

If needed, multiple repeaters can be used. The repeaters draw their own power allowing a single controller to be used for any length of strips.

Power injection for digital LED strips

For digital strips, the voltage for each LED is controlled by microcontrollers mounted on the strip. The microcontrollers require the full amount of voltage from the power supply, so power injection is done by wiring the power supply directly to the strip.

With a single power supply, power can be injected by simply connecting the power supply wires to the V+ and V- wires wherever additional power is needed.

NOTE: Not all addressable strips require the “Clock” wire as shown in the diagrams. Whether it’s required depends on the type of microcontroller the strip uses.

With multiple power supplies, the technique is the same except that V+ is not connected between power supplies.

WARNING: Never connect the positive wires between power supplies. This can destroy power supplies and potentially start fires.

How to select the right wire size

Thick wire will have less voltage drop than a thin wire. Therefore, if you need to run wires for long distances, the thicker the better.

However, thick wire is more expensive. It’s more difficult to hide. And, if you are trying to fish wires through walls, thick and rigid wires can make your job quite difficult.

To select the right size wire, you need to know the:

- Strip Voltage

- Current – In order to calculate the required current, divide the total required power by the voltage. For example, a 100W 12V strip requires 100W/12V = 8.3A.

- Length of wire

- Acceptable amount of voltage drop

Then, plug in the values into this calculator. Adjust the wire size and recalculate until you get an acceptable amount of voltage drop.

If you will be installing the wires inside finished walls, the wiring should be labeled as class 2 compliant.

How to control LED strips

This section explains how to automate or wirelessly control the LED strips using smart home products.

Do I always need a controller?

If you have a single color LED strip, you wouldn’t necessarily need a controller. You could just connect it directly to a power supply.

Then, if you wanted to turn it into a smart light, you could plug the power supply into a smart plug. It works, but it’s very basic.

However, even if you don’t care about changing colors, most people will at least want the ability to dim. And in order to do that, you will need a controller.

How to dim LED strips

There are two common ways to dim LED strips using smart control.

The first way is to use a smart AC dimmer installed in the wall. In order to do this, the wiring goes from the dimmer switch to the power supply to the lights.

Pros/Cons of this method:

Con – You must have a dimmable power supply for this to work. These are usually more expensive than regular power supplies.

Pro – You can use any standard dimmer including smart dimmers like the Lutron Caseta dimmers.

Pro – When the lights are turned off, the power supply is turned off. This eliminates a source of “vampire” power.

Con – Only works with single color LED strips.

A second way is to use a smart controller. Here, the wiring goes from the power supply to the controller to the lights.

Pros/Cons of this method:

Pro – Smart controllers can control strips with multiple colors.

Pro – Doesn’t require a dimmable power supply.

Con – The lights are not wired directly to a wall control. In order to have control at the wall, it would require installing one of these extra smart switches at the desired location to communicate with the LED controller.

Con – The power supply is always on resulting in a source of vampire power.

This second method is my preferred way to do it. I’m a huge fan of color changing lights. Even if it’s in an area where I don’t need full color, I still want the ability to do white color shifting. I’m a big believer in using circadian lighting whenever possible.

How to control LED strip color

If your LED strips are color changing strips, you will need a smart controller.

Make sure your controller has enough channels. If you have an RGBW strip, you need a controller with 5 output terminals. One terminal is the supply voltage (V+). The other four terminals are for each of the R, G, B, and W LEDs.

It’s okay to use a controller with too many channels. However, be aware that there is a limit to how much current can run on each channel.

A controller has a limit to how much current can be ran through it. For example, this RGBGenie controller can handle up to x amps.

In most cases, voltage drop will cause problems long before your controller runs out of capacity.

Wireless protocols

A smart LED controller communicates with your smart home using some kind of wireless “language” (protocol). You have basically three protocols to choose from: WiFi, Zigbee, or Z-Wave.

If you don’t have any other smart home stuff, I recommend sticking with a WiFi controller. It doesn’t require an additional hub (uses your WiFi router) and tends to be cheaper than the other two options..

Zigbee and Z-Wave are both wireless protocols designed specifically for home automation. With one of these controllers, you can connect your controller to a smart hub like Samsung SmartThings and your automation possibilities will be endless.

I prefer the Zigbee protocol for my lights because it works with the Philips Hue hub. The Hue hub is very reliable and has super fast reaction times. Plus, I already have a bunch of Philips Hue lights so my Hue mesh network is strong.

NOTE: If you want your controller to be compatible with Hue, you have to make sure it’s a Zigbee 3.0 certified controller.

Where to install the controller

Controllers are usually much smaller than power supplies so they are easier to hide.

In most installations, it makes sense to install the controller as close to the strips as possible.

If necessary, run heavy gauge wire from the power supply to the controller to minimize voltage drop. Then switch to lighter gauge wire from the controller to the strips.

How to control individually addressable LED strips

For analog strips, all LEDs of the same color are wired to a single channel. A single controller can adjust the power to each channel independently, but cannot adjust the LEDs individually.

Addressable LED strip control is very different from analog. I am far from an expert in setting up addressable LED strip controls. However, the basic requirements are as follows:

- In order to use digital control, you must first have a digital LED strip.

- In addition, you will need a computer (many people use an Arduino or a Raspberry-Pi) to process code and send the signal to the LED microcontrollers mounted on the strip.

- Finally, you will also need to supply the computer with a program that tells the microcontrollers how to run the lights.

Once you add the ability to be able to control each individual LED independently of others, you can create much more powerful effects. Marlon at hometechhacker.com has this cool page showing what is possible with a little tinkering and a super-cool program called WLED. In addition, he has a few other articles that explain in more detail about how to set it up.

Recommended Products

Do a Google search for LED strips and you will get pages of results with countless vendors selling their strips and accessories.

There’s so many that I can’t say which ones are best. But, I can tell you which ones I’ve used and whether they worked for me.

As I continue to buy and test items, I will keep this list up to date.

LED Strips

High CRI (Daylight White) – MARSWALL LED Strip CRI 97+

RGBW – BTF-LIGHTING 16.4ft RGBW 4 in 1 LED Strip

LED Controllers

WiFi

Z-Wave

Works with Hue – GIDERWEL Zigbee RGBW LED strip controller

Power Supplies

Class 2 (CL2) – 12V 60W Power supply

Dimmable – HitLights 12V 60W dimmable LED driver

Final Thoughts

When I called this the “Ultimate Guide to LED Strips”, I meant it. I want this to be the biggest, baddest guide that will get you from zero knowledge to finished project.

But, I’ll admit that I don’t know everything there is to know about LED strips and this guide isn’t perfect. So, if you have any tips or things I missed, please let me know in the comments below and I’ll add it to the guide.

Thanks for reading!

Comments are closed.